Insights from Research and Practice

Developing innovative software like ADVISIM3D is like having a crazy idea and letting caring software engineers tame it and raise it. In 2020, the time came to release it into the wild. Since then, ADVISIM3D has proven itself in tough industrial practice. The virtual cleaning simulation is convincing not only an increasing number of customers, but - according to a recent comparative study - also researchers at TU Dresden. Here you can stay up to date on all major developments.

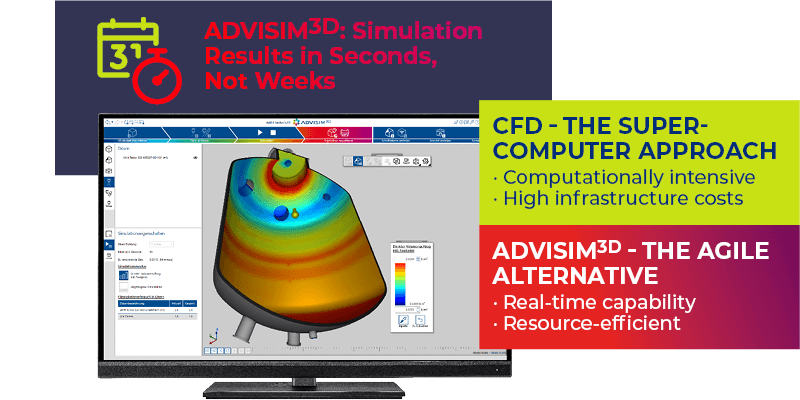

TU Dresden Pits ADVISIM3D Against CFD in a Showdown

In a scientific study, TU Dresden compares the simulation results of mathematical CFD simulations with those of ADVISIM3D. In other words: high-performance computing on 480 cores versus a standard PC environment. Around one month of computation time to simulate 1.25 seconds of a real cleaning process versus just a few seconds with ADVISIM3D. The result: The deviation between the simulation outcomes is only 0.6%. Discover why ADVISIM3D’s minimax strategy—achieving maximum insight with minimal effort—proves so successful in terms of time and cost efficiency, and how you can dramatically shorten your CIP planning cycles while maintaining full safety and scientifically validated reliability.

We have placed the scientific comparative study conducted by TU Dresden at the heart of an exclusive LinkedIn article series:

“CFD vs. ADVISIM3D – The Cleaning Simulation Showdown.”

- Part 1 traces the duel back to the famous scientific dispute between Leibniz and Newton.

- Part 2 reveals who ultimately emerges as the winner of the showdown.

- Part 3 makes one thing clear: when it comes to CFD and ADVISIM3D, it’s not about either–or, but about both–and.

Instead of a spectacular yet dry scientific paper, we tell a compelling story about the disruptive potential of a new approach - one that carries real impact for engineering departments in plant and vessel construction.

Don’t miss a thing: follow ADVITEC Informatik GmbH on LinkedIn and stay up to date.

Are you considering whether cleaning simulation with ADVISIM3D might be the right fit for your application? We would be happy to discuss your requirements, introduce ADVISIM3D personally, and answer all your questions.

Call us to schedule an appointment: +49 351 6526222 or simply use the contact form

___________________________________________________________________________________________

⭸ twitter.com/ADVITEC

⭸ twitter.com/advisim3

⭸ ADVITEC bei Linkedin

⭸ ADVITEC bei XING

What can a virtual cleaning simulation achieve in the hands of an experienced ZETA engineer?

ZETA Holding GmbH is a leading internationally operating company in plant engineering and automation for the biotech and pharmaceutical industries. With the introduction of the virtual cleaning simulation ADVISIM3D, ZETA gains significant added value in the optimized planning and design of CIP (Cleaning in Place) systems. This user story highlights the practical interaction between ZETA process engineers and ADVISIM3D during the design phase of cleaning systems. It shows how the intelligent use of a digital assistant improves both efficiency and communication within the project environment.

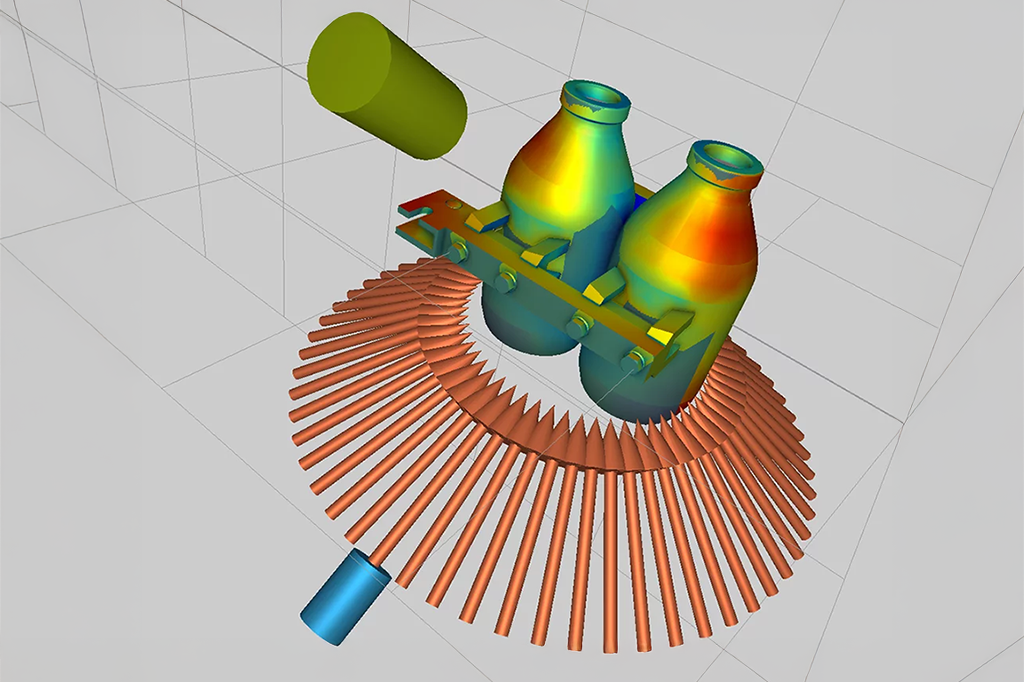

Highly precise simulation of spray shadows and flow rates

In the hands of the process engineers responsible for cleaning validation, ADVISIM3D has proven to be a valuable tool for realistically simulating the cleanability of vessels and systems. For ZETA, it is crucial not to view simulation results as isolated data, but to interpret them realistically within the context of practical experience.

ZETA’s engineers contribute the necessary expertise - and intuition - to plausibly validate simulation results for specific configurations.

Practical experience shows that ADVISIM3D reliably maps spray shadows and direct volumetric flow application. In a specific use case, this helped process engineers increase both efficiency and safety in the cleaning design of a fermenter. Support from ADVISIM3D not only enables precise advance planning of cleaning processes, but also provides a safety advantage: the simulation is based on a standardized soil that is more difficult to remove than riboflavin, which is commonly used in cleanability tests.

Strategic application areas of ADVISIM3D from an engineering perspective

ZETA’s process engineers primarily use ADVISIM3D in projects with particularly complex cleaning requirements, such as challenging contaminations. In these cases, the software supports the determination of optimal nozzle configurations and thus the optimization of the cleaning process.

ADVISIM3D also plays an important role in communication with vessel manufacturers. The simulation results provide an objective basis for discussions about design proposals, significantly improving collaboration between plant engineers, vessel manufacturers, and experienced end users.

The best of both worlds: virtual and human excellence

At ZETA, ADVISIM3D has become an established tool for increasing planning reliability, making development processes more efficient, and optimizing the cleanability of vessels and systems at an early stage. Combined with the expertise of experienced process engineers, the software becomes a strategic instrument that not only reduces error rates in early project phases, but also significantly improves communication and quality assurance.

By combining state-of-the-art simulation technology with in-depth engineering knowledge - such as the nature of contaminants, the properties of cleaning media, and optimal nozzle positioning - ADVISIM3D enables precise predictions of cleaning performance under real operating conditions.

This integrative approach strengthens ZETA’s position as an innovation leader in the biotech and pharmaceutical industries and underscores the added value that virtual cleaning simulation delivers when combined with human expertise.

Are you interested in whether cleaning simulation with ADVISIM3D could also be suitable for your application? We would be happy to talk about it, personally introduce you to ADVISIM3D and answer all your questions. Give us a call and make an appointment on +49 351 6526222 or use the form

___________________________________________________________________________________________

⭸ twitter.com/ADVITEC

⭸ twitter.com/advisim3

⭸ ADVITEC bei Linkedin

⭸ ADVITEC bei XING

Hygiene Meets High Tech: SIG Relies on ADVISIM3D for Global Food Safety

The North Moluccas—ever heard of them? And what does this diving paradise in northern Indonesia have to do with the virtual simulation software ADVISIM3D for industrial spray cleaning processes? Quite a lot, as it turns out. Even in this exotic location, SIG’s state-of-the-art packaging machines demonstrate their superior technological expertise in the hygienically safe, aseptic filling of food products.

To optimize its machine development, SIG - a company with around 9,000 employees and annual revenues of €3.2 billion - has been using the standard software ADVISIM3D for the packaging industry and plant engineering since 2021. The software is developed by the Saxony-based software company ADVITEC Informatik GmbH.

The goal

A carton package must safely preserve fruit juices or coconut milk for many months without refrigeration - at average temperatures of around 30 °C - and ensure food safety and product stability even under the most demanding climatic conditions, such as those found in the North Moluccas.

To achieve this, SIG has developed its aseptic filling technology. It delivers maximum food safety and quality with a shelf life of up to 12 months - without the need for energy-intensive cooling or the use of preservatives.

New systems or prototypes must be commissioned and validated directly at customer sites. Since R&D staff from Linnich - the German development and production site - often have to travel long distances with multiple stopovers to reach customers, for example in Brazil, variants and operating scenarios are analyzed as early as possible in the development process.

The challenge

Aseptic filling and packaging machines place extremely high demands on the cleanability of all pipelines and surfaces that come into contact with food. As a result, the entire development process of such high-tech equipment follows the principles of hygienic design. Nevertheless, even systems that must fill products under absolutely sterile conditions were traditionally equipped with CIP (Cleaning in Place) systems for pipe cleaning, while additional manual cleaning steps were still required.

The solution

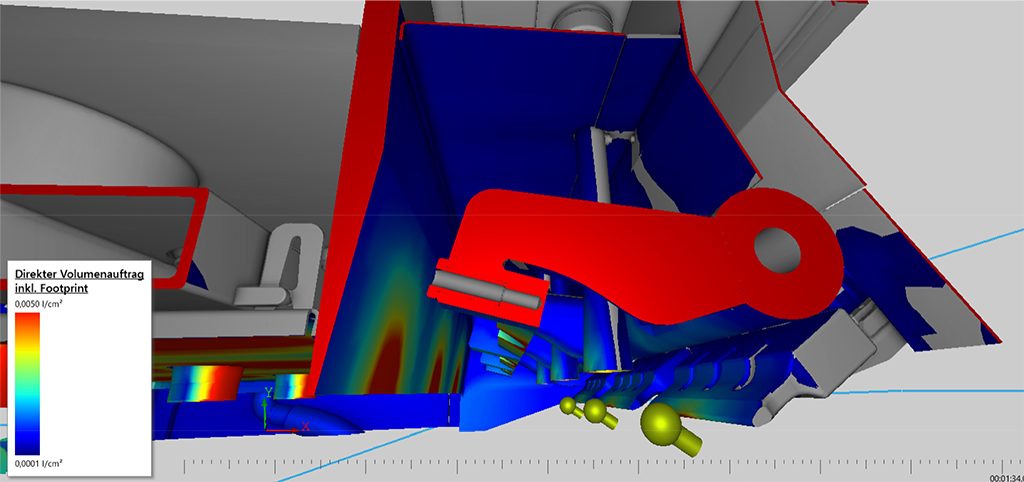

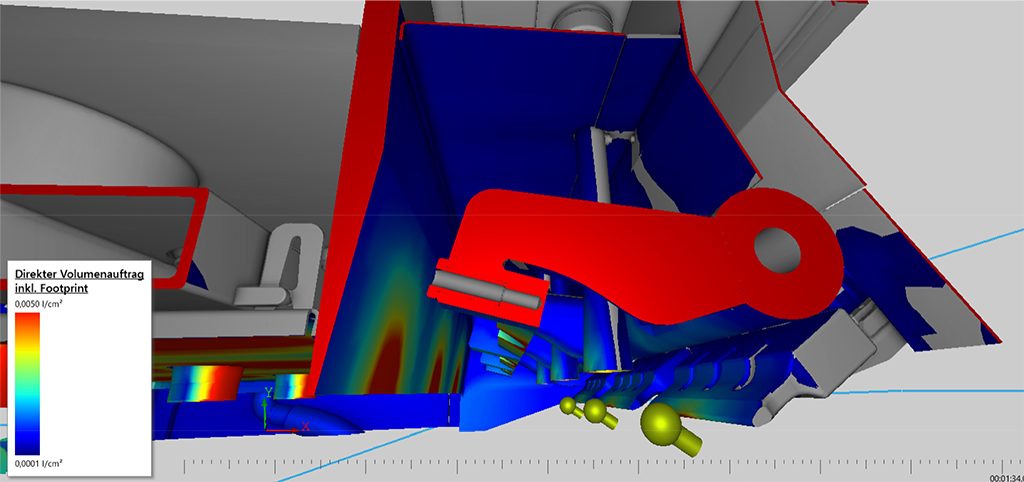

Modern machines are characterized by an increasing degree of automated cleaning processes. Various nozzle types - such as rotating nozzles, flat spray nozzles, and full-cone nozzles - are used. In addition to physical testing, SIG relies on state-of-the-art digital methods for the design and layout of these demanding processes.

At SIG, ADVISIM3D was used for the first time in the fundamental new development of an aseptic filling machine, supporting the selection and positioning of cleaning nozzles.

The machine’s sterilization chamber to be cleaned has a highly complex design with numerous internal components, undercuts, and spray shadows. ADVISIM3D enabled engineers to virtually simulate the cleaning effectiveness of different nozzle types and arrangements, allowing them to identify the optimal configuration quickly, easily, cost-effectively - and above all, in full compliance with hygienic design requirements.

Benefits of simulation

Simulation makes it possible to optimize the cleaning process during the development phase, before the machine is physically built. This saves both time and costs, as extensive modifications to real machines can be avoided. The simulation also allows the number of required nozzles to be reduced while still ensuring effective cleaning. Potential weaknesses in the cleaning design can thus be identified and eliminated at an early stage.

Validation of the simulation

Some of the simulation results were validated through tests on real machine components. These tests showed that the simulation reflects reality very accurately in the vast majority of cases. In the few instances where deviations occurred - such as in the simulation of draining water - the engineers’ practical experience was used to realistically interpret and adjust the simulation results.

Conclusion

The use of ADVISIM3D has helped SIG design cleaning processes for new aseptic filling machines more efficiently and effectively. The simulation software accelerates development, reduces costs, and eliminates the need to oversize cleaning processes purely for safety reasons.

SIG uses ADVISIM3D as a digital assistant to complement the engineers’ experience, acknowledging that simulations cannot perfectly represent reality in every detail.

By combining simulation with real-world testing, SIG ensures that its state-of-the-art aseptic filling machines with fully automated cleaning meet the highest standards of cleanliness and sterility—worldwide, even in the most remote locations such as the North Moluccas.

Are you interested in whether cleaning simulation with ADVISIM3D could also be suitable for your application? We would be happy to talk about it, personally introduce you to ADVISIM3D and answer all your questions. Give us a call and make an appointment on +49 351 6526222 or use the form

___________________________________________________________________________________________

⭸ twitter.com/ADVITEC

⭸ twitter.com/advisim3

⭸ ADVITEC bei Linkedin

⭸ ADVITEC bei XING

ADVISIM3D optimises container interiour cleaning at Pharmatec GmbH, a Syntegon Company

In the manufacture of pharmaceuticals, customers of Dresden-based Pharmatec place high demands on the quality of the cleaning of containers and production facilities. In modern plants, production residues are removed using automated cleaning systems. A particular problem arises with containers with large volumes and diverse or complicated internals.

Pharmatec, a Syntegon Group company based in Dresden, Germany, offers complete solutions for the production, distribution and storage of high-purity media such as HP, HPW, PS and WFI. In addition, pharmaceutical manufacturers receive modern formulation systems for large and small-volume parenterals as well as tried and tested, practice-orientated bioprocess systems and services including future-proof automation solutions. The focus is on hygienic and sterile processes for pharmaceuticals, biotechnology, cosmetics and other good manufacturing practice industries in quality assurance.

The challenge

In the production of pharmaceuticals, our customers place high demands on the quality of the cleaning of containers and production facilities.

In modern systems, production residues are removed using automated cleaning systems. A particular problem arises with large-volume containers and diverse or complicated installations. Here, agitator parts, inlet pipes or measuring technology can protrude into the tank interior. These installations form spray shadows and hinder the cleaning of product residues by spray balls or cleaning nozzles installed in the tank.

However, the optimum positioning of the spray balls in the container is crucial for the quality and efficiency of the cleaning process. Until now, this task has been performed on the basis of empirical values and, in cases of doubt, with complex test trials. This is resource-intensive and often leads to oversized systems in order to guarantee reproducible cleaning success.

Solution with ADVISIM3D

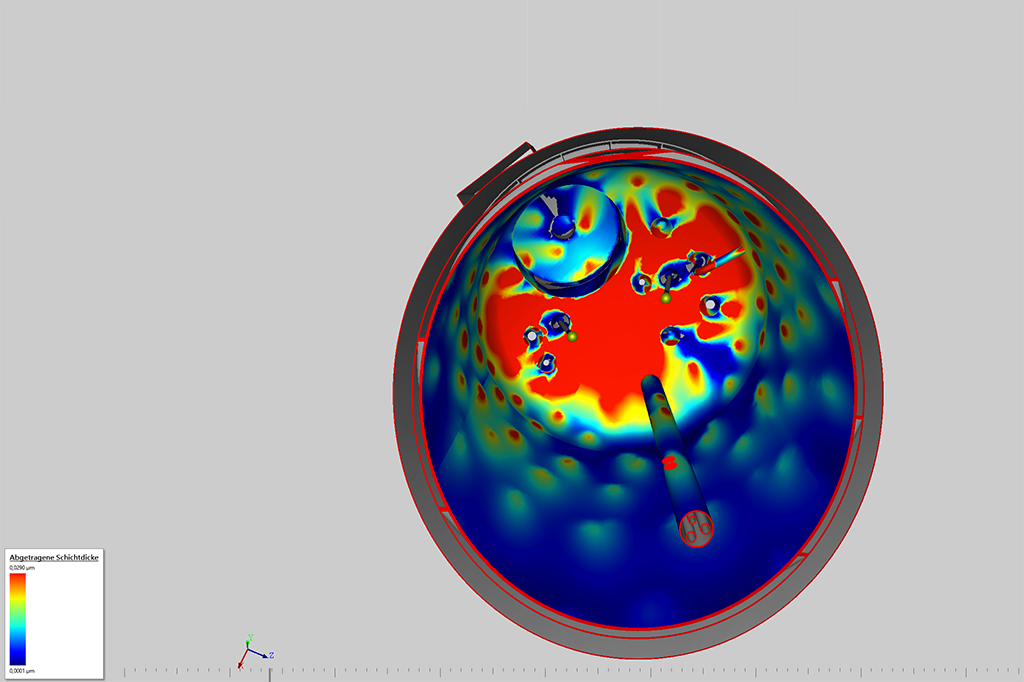

Pharmatec uses the 3D cleaning simulation software ADVISIM3D from ADVITEC to optimise the planning and validation of CIP cleaning processes. The software enables the virtual simulation of spray cleaning processes, the analysis of spray shadows, volume flow distribution and cleaning effect.

Advantages and benefits

• Time and cost savings:

The virtual simulation allows different nozzle configurations and cleaning parameters to be tested quickly and easily without having to carry out complex analogue tests. This significantly reduces the time required for the design, dimensioning and validation of cleaning systems.

• Conservation of resources:

Avoiding spray shadows and oversizing through optimised nozzle configurations leads to lower consumption of cleaning media, water and energy.

• Better cleaning results:

The ability to virtually test a variety of configurations allows Pharmatec to find the optimal balance between effort and benefit in achieving the cleaning goal.

• Transparent documentation:

ADVISIM3D enables the creation of meaningful documentation. The simulation results can be output as colour visualisations and reports and stored in the technical documentation for cleaning planning.

Cooperation with ADVITEC

Pharmatec was already involved as a competence partner in the SIMKOR research project, which served as the basis for the development of ADVISIM3D. Pharmatec's practical tests under real-life conditions provided valuable insights for the development of a meaningful cleaning simulation.

Conclusion

The use of ADVISIM3D enables Pharmatec to design cleaning processes for internal container cleaning for customers in the pharmaceutical industry in a more efficient and resource-saving manner. The simulation can save time and costs right from the planning phase, improve cleaning quality and at the same time fulfil the strict requirements of the pharmaceutical industry.

"ADVISIM3D sets an unrevalled standard in the simulation of container interior cleaning. The 3D visualization and user-friendliness are impressive and the results are precise and save costs for expensive test series and conversions." Torsten Große - Design Manager | Standardization and Design Requirements (PADD/ENG-N) | Syntegon Technology GmbH

Are you interested in whether cleaning simulation with ADVISIM3D could also be suitable for your application? We would be happy to talk about it, personally introduce you to ADVISIM3D and answer all your questions. Give us a call and make an appointment on +49 351 6526222 or use the form

___________________________________________________________________________________________

⭸ twitter.com/ADVITEC

⭸ twitter.com/advisim3

⭸ ADVITEC bei Linkedin

⭸ ADVITEC bei XING

ADVISIM3D revolutionises bottle cleaning in pharmaceutical filling and packaging technology at Bausch+Ströbel SE Co. KG

High demands are placed on the cleaning of pharmaceutical machines and containers. For example, bottles for storing and transporting vaccines must be cleaned hygienically before filling in order to reliably remove possible contamination from production, packaging or transportation. A second cleaning process concludes production in order to remove any residue from the outside of the bottles and make the containers ready for transportation.

Bausch + Ströbel, a leading global provider of pharmaceutical packaging solutions with almost 60 years of company history and numerous awards, relies on the virtual cleaning simulation ADVISIM3D. In its own approach, the company uses the software, which is usually used for the internal cleaning of containers, to successfully simulate and optimize the external cleaning of bottles virtually.

The challenge

The bottles are held in place by machine clamps and guided past the cleaning nozzles - static full-cone nozzles at the top and vertically movable flat ejectors at the bottom. WFI water (Water For Injection) is used as the cleaning fluid and compressed air is used for drying. The machine clamps cast spray shadows, making cleaning more difficult. WFI is also comparatively expensive.

The target for optimizing the positioning of the nozzles and clamps using the ADVISIM3D virtual cleaning simulation is a 50 percent saving in WFI, which in this case corresponds to around 250 l/h. In addition, the number of time-consuming cleaning cycles is to be reduced. In addition, the number of time-consuming and cost-intensive analog cleaning tests with riboflavin or diatomaceous earth corn starch should also be halved as far as possible.

The solution

With ADVISIM3D, any number of scenarios can be simulated virtually, without physical prototypes or complex test setups. Different new nozzles, bottle sizes and bottle quantities as well as nozzle positioning and gripper arrangements are simulated. The results of the simulations with direct volume flow application and removed layer thicknesses between 30 and 55 µm match the photo-documented results of the analog tests.

The advantages

The virtual optimization of external bottle cleaning with ADVISIM3D delivers convincing results. Weak points in the cleaning process, such as areas covered by the holding clamps that are difficult to clean, are identified and eliminated. By making targeted adjustments to the nozzle positions and the mounting of the holding clamps, e.g. smaller mounting surfaces, larger distances and modified holding positions, Bausch + Ströbel can continuously improve the cleaning performance and at the same time reduce the consumption of expensive WFI water. The number of physical test runs required is actually halved from 5-6 to 2-4, which saves a lot of time and money.

Prospects

The successful use of ADVISIM3D outside of the usual application scenarios in container interior cleaning demonstrates the flexibility and enormous potential of this innovative virtualization software. Bausch + Ströbel is also planning to use ADVISIM3D for the cleaning simulation of machine surfaces and for large CAD models with more than 10,000 components, underlining its confidence in the software as a reliable digital assistant and an innovative and efficient virtualization solution in pharmaceutical filling and packaging technology.

Are you interested in whether cleaning simulation with ADVISIM3D could also be suitable for your application? We would be happy to talk about it, personally introduce you to ADVISIM3D and answer all your questions. Give us a call and make an appointment on +49 351 6526222 or use the form

___________________________________________________________________________________________

⭸ twitter.com/ADVITEC

⭸ twitter.com/advisim3

⭸ ADVITEC bei Linkedin

⭸ ADVITEC bei XING

ADVITEC Manufacturer Report | Why we developed ADVISIM3D and brought it to market maturity

ADVISIM3D is the market-leading digital answer to the current analog challenges of hygiene safety, resource and environmental protection in industrial cleaning. Together with our cooperation partners in the publicly funded SIMKOR research project, we recognized the need for a virtualization solution for the planning, validation and optimization of spray cleaning processes at an early stage. Conventional methods based on analog tests were time-consuming and resource-intensive and often led to oversized cleaning systems for safety reasons.

Together with our cooperation partners in the publicly funded SIMKOR research project, we recognized the need for a virtualization solution for the planning, validation and optimization of spray cleaning processes at an early stage. Conventional methods based on analog tests were time-consuming and resource-intensive and often led to oversized cleaning systems for safety reasons.

As a leading research institute in the field of static and dynamic spray cleaning, the Fraunhofer Institute for Process Engineering and Packaging (IVV) Dresden was an important initial source of inspiration. The institute has many years of experience in cleaning technology, particularly in the experimental research of interactions and in the monitoring and recording of cleaning processes. As part of SIMKOR, the Fraunhofer IVV Dresden was responsible for collecting the metrological data. Comparable data also form the physical basis for reliable and realistic predictions of the cleaning effect of ADVISIM3D.

Since its market launch in 2021, ADVISIM3D has been continuously developed and improved to meet the requirements of users in the field and to establish the software as the industry standard for the pharmaceutical, food, manufacturing and other sectors.

Arguments in favor of the ADVISIM3D virtual cleaning simulation

- Resource efficiency: ADVISIM3D can be used to virtually simulate and optimize cleaning processes in order to reduce the consumption of cleaning fluids, water and energy.

- Accuracy and reliability: The software is based on scientific data and algorithms provided by the Fraunhofer IVV Dresden as part of the SIMKOR project, enabling precise simulations and valid statements about the cleaning effect.

- Time and cost savings: ADVISIM3D accelerates the design and validation process of cleaning systems, reduces the need for time-consuming analogue tests and minimizes downtimes.

- Improved transparency and documentation: The software provides a 3D visualization of the cleaning process and enables automated reporting. This increases transparency and simplifies documentation.

- Continuous innovation: ADVITEC regularly optimizes and updates ADVISIM3D to meet the changing requirements of the industry and to integrate new functions.

Conclusion

"ADVISIM3D is the first market-ready product of our strategic development offensive 'Software for industrial cleaning'. Since 2015, ADVITEC has been building up in-depth expertise in the digitalization of cleaning processes, particularly in the areas of virtual simulation and robot control. We regularly contribute our expertise to research and funding projects with partners from science, industry and politics. Our common goal: resource optimization through more efficient cleaning processes for the benefit of the environment, society and companies."

Norbert Ebersbach - Managing Director and Product Manager | Project ADVISIM3D | ADVITEC Informatik GmbH

___________________________________________________________________________________________

⭸ twitter.com/ADVITEC

⭸ twitter.com/advisim3

⭸ ADVITEC bei Linkedin

⭸ ADVITEC bei XING