ADVISIM3D vs. CFD

The Cleaning Simulation Showdown – Part 2

7 January 2026 | The match-up in this comparative study is extreme.

What happens when the same cleaning task is tackled by CFD - the Goliath of simulation - and ADVISIM3D - the David among virtual cleaning simulations, under radically different study conditions?

- EuroHPC supercomputer MeluXina using 480 computing cores vs. a standard PC environment

- Hardware investment of several million euros vs. €2,500

- Software license including CFD of approx. €40,000 vs. ADVISIM3D annual license of €4,150

The Technical University of Dresden (Institute of Natural Materials Technology) conducted exactly this comparison. The outcome is not only surprising—it is direction-setting for modern CIP system design.

THE STUDY: WHEN MATHEMATICAL THEORY MEETS PHYSICALLY MEASURED REALITY

The scientific challenge: validating the cleanability of a vessel cleaned by a rotating spray cleaner. Which simulation comes closer to real-world results?

1. The highly complex CFD approach (Computational Fluid Dynamics)

- Basis:Mathematical theory for calculating droplet trajectories, atomization, and volumetric flow.

- Time required:Approximately one month of computation time to simulate 1.25 seconds of physical cleaning time.

2. The specialized ADVISIM3D approach

- Basis:Physical projection based on empirically measured spray patterns.

- Time required: The complete simulation - including result output - takes just a few seconds.

THE RESULT

Precision is not a question of computing power

It was initially assumed that the massive use of supercomputing resources would lead to significantly more accurate results. However, the researchers arrived at a very different conclusion: The deviation between the wetted areas identified by the two simulations is only 0.6%.

When it comes to identifying critical “shadow zones” (spray shadows), both methods deliver virtually identical results. This proves one key point:

For validating cleanability - and thus for software-based CIP system design - maximum computing power does not equal maximum insight.

KEY TAKEAWAYS FOR CLEANING ENGINEERS

For everyday engineering practice, this means:

- Massive time savings: Planning cycles shrink from weeks to seconds

- Minimal infrastructure: Validation directly on a PC instead of external supercomputers or costly server clusters

- Real-time capability: Design optimizations can be simulated and adjusted immediately

- Proven reliability: A deviation of just 0.6% ensures reliable identification of spray shadows

- Efficiency focus: No waste of resources—with equal informational value

IS CFD OBSOLETE NOW?

Absolutely not. Part 3 of the simulation showdown will answer the following questions:

- Why was ADVISIM3D able to perform so well in the scientifically rigorous TU Dresden comparative study?

- How can ADVISIM3D and CFD work together efficiently in plant and vessel design?

Coming soon …

Would you like to try ADVISIM3D ? We look forward to hearing from you personally at test ADVISIM3D

We look forward to hearing from you.

ADVISIM3D means: Digitize effort - maximize analog benefit.

twitter.com/ADVITEC

twitter.com/advisim3

ADVITEC bei Linkedin

ADVITEC bei XING

ADVISIM3D vs. CFD

The Cleaning Simulation Showdown – Part 1

17 December 2025 | Two radically different approaches to virtual cleaning simulation are currently shaking up the world of nozzle manufacturers, plant engineers, and vessel/tank builders. In engineering departments, a veritable belief war is raging: Team ADVISIM3D or Team CFD?

The roots of this debate go back to Isaac Newton and Gottfried Wilhelm Leibniz. At the end of the 17th century, a fierce scientific dispute erupted between them. Today, we know that both independently invented calculus. Yet the fundamental differences in their methods and ways of thinking continue to divide engineering teams - and determine the efficiency of plant design to this day.

The simulation approaches of Computational Fluid Dynamics (CFD) and ADVISIM3D could hardly be more different. And yet, they pursue the same goal in plant design: virtualizing Cleaning-in-Place (CIP) to transfer analog processes into the digital world. This creates transparency and saves not only engineering hours, but also valuable resources.

THE SPIRIT OF LEIBNIZ: CFD

Team Leibniz believes in the mathematical-theoretical approach. The search is for a universal, mathematically describable truth—and it is found in highly complex CFD simulations.

Their ambition is fascinating: calculating every water droplet and every boundary layer, solving the Navier–Stokes equations, and breaking the world down into a perfect mathematical grid.

CFD is an attempt to recreate reality from first principles—purely through mathematics—inside a computer. Much like Leibniz’s derivation of calculus, it represents the path of highest theoretical elegance.

At the same time, CFD simulations place correspondingly high demands on IT infrastructure and computation time.

THE SPIRIT OF NEWTON: ADVISIM3D

Team Newton believes in the physical-empirical approach. Newton started from observable results. His modern representative is ADVISIM3D.

The key question is not: “How should a droplet move according to the formula?”

But rather: “What does the nozzle actually do in reality?”

ADVISIM3D uses physically measured spray patterns and projects them virtually into the geometry. Much like Newton’s development of integrals, this is the path of radical practical usefulness.

ADVISIM3D simulations run on standard PC hardware and deliver results in seconds.

BUT HOW VALID ARE THE RESULTS OF BOTH SIMULATION METHODS?

The showdown: What happens when the two approaches go head-to-head? The same task. The same tank. The same nozzle. High-performance computing vs. a standard PC. Mathematical theory vs. physical empiricism.

The Faculty of Mechanical Engineering at TU Dresden did exactly that. And the outcome is explosive - not only for those who still design plants purely analog based on experience and experimental trials, but also for engineers caught in the belief war between CFD and ADVISIM3D.

Part 2 of “LEIBNIZ VS. NEWTON – CFD VS. ADVISIM3D”

January 7, 2026

THE RESULT OF THE ULTIMATIVE COMPARATIVE TEST

Would you like to try ADVISIM3D ? We look forward to hearing from you personally at test ADVISIM3D

We look forward to hearing from you.

ADVISIM3D means: Digitize effort - maximize analog benefit.

twitter.com/ADVITEC

twitter.com/advisim3

ADVITEC bei Linkedin

ADVITEC bei XING

ADVISIM3D 2.0

Being a child for once - in a complex CIP spray cleaning system ...

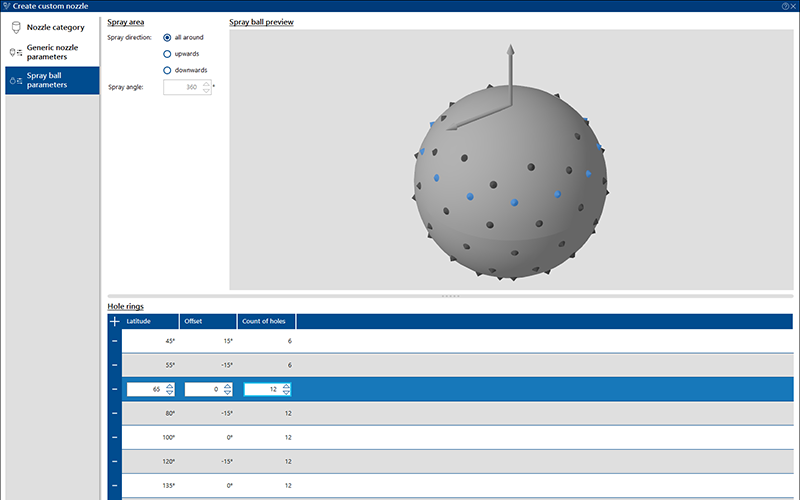

4 March 2024 | With ADVISIM3D, even the most serious engineer can do it. The new major release 2.0 revives your old spirit of adventure. Drilling holes, expanding, spraying around to your heart's content and doing good at the same time? With the new spray ball designer, you can now create your own or modify existing spray balls in any size and with holes according to your requirements. You can place them anywhere in your tank model and also benefit from the new view-based cutting plane in the virtual cleaning simulation

ADVISIM3D 2.0 provides extension from manufacturer nozzles to spray balls that can be freely costomized

Three years after the product launch, ADVITEC is upgrading its virtual cleaning simulation ADVISIM3D to major release 2.0. In the next digitalization step in the industrial spray cleaning of containers and components, engineers can now adapt existing spray balls and create completely custom spray balls for the first time.Whether size, number and position of the holes - everything is freely definable.You can then place your spray balls anywhere in the model and receive an instant spray shadow analysis.

When is a product innovation such as the ADVISIM3D virtual cleaning simulation for the pharmaceutical, food and manufacturing industries successful? Our answer is Major Release 2.0. It has taken us six years to develop ADVISIM3D from the SIMKOR research project launched in 2015 for the virtual cleanability simulation of complex spray cleaning systems into industry-standard software.

But the spirit of innovation does not stop with the product launch. Since 2021, there have been nine interim versions with hundreds of improvements, bug fixes and additions to the features and nozzle catalog. Dozens of customer meetings and three years later, ADVISIM3D has made it into the first major release 2.0. Persistence, perseverance and patience are also part of a sustainably successful innovation project - and we and our customers are far from finished. From version 2.0 onwards, you will also benefit from the view-based cutting plane, which always automatically aligns itself parallel to the current perspective at a certain distance from the model.

In addition, the nozzle catalog has been expanded to include many manufacturer nozzles, which you can find in the Release Notes 2.0. The ideal nozzle configuration can now be selected from approx. 150 manufacturer nozzles as well as individually configurable spray balls.

Let us convince you of the added value of the new functions and improvements, especially the option to design your own spray balls and modify existing ones. Do you have any questions, suggestions or would you like to test ADVISIM3Din Major Release 2.0? Then we look forward to hearing from you.

ADVISIM3D means: Digitize effort - maximize analog benefit.

twitter.com/ADVITEC

twitter.com/advisim3

ADVITEC bei Linkedin

ADVITEC bei XING

Simulate spray cleaning

Measuring or calculating? This is the question here!

1 February 2023 | Do you need to know why and how an apple falls from a tree to find out on which surface it will be distributed upon impact? CFD says yes to mathematics, ADVISIM3D chooses physics, the goal of both is the same: Both want to use a virtual simulation to determine the optimal type, number and positioning of nozzles to certify a container theoretically cleanable based on a specific nozzle configuration.

Whether an analog cleaning process based on this is actually successful depends on many other factors such as the type of contamination, the chemical used, temperature or duration of the cleaning process.

However, while CFD simulations are enormously resource-hungry in terms of training, simulation time and computing power, ADVISIM3D delivers valid cleanability results within minutes in a normal PC environment. How can this be? And above all: Doesn't this mean that the decision about the better approach has already been made?

Not at all! If you want to design a nozzle, for example, you can't get around CFD, because CFD can be used to simulate complex problems such as turbulent flows, the flight characteristics of droplets or effects in the boundary layers. In addition, there are effect interdependencies between droplets or between droplets and their surroundings, such as the tank wall, and much more. All this has to be described mathematically and the results calculated approximately in the form of highly complex nonlinear differential equations. Given sufficient computing capacity and time, a wide range of effects such as impact angle, wall shear stress, droplet sizes or complex flows can be captured and investigated in isolation. CFD is a powerful tool for specialists who want to find as many answers to as many questions as possible.

ADVISIM3D makes it simple and asks only one question: Is every point of the vessel sufficiently wetted by the cleaning medium? The answer is provided by a simulation that delegates the main effort to the collection of the underlying data. This is because they are not calculated mathematically, but obtained physically on analog nozzle measuring stands at the Fraunhofer IVV in Dresden in the form of real spray patterns. These comparatively few parameters can be synthesized within a few minutes in a simple PC environment as a spray shadow analysis with volume flow distribution, thus simulating the cleanability of a container.

Whether it is an advantage or disadvantage that ADVISIM3D delivers no less, but also no more than exactly that, depends on the user's application scenario. The designer of a tank does not care why and under consideration of which effects the cleaning medium hits where. The designer of a nozzle, on the other hand, does not care why a certain spray pattern is produced, taking into account as many effects as possible. He must know as precisely as possible all the adjusting screws that lead him to the desired result. In this respect, complexity is not only acceptable, but desirable. And the fact that extensive calculations take a very long time and that it is not exactly trivial to set up a CFD correctly in order to arrive at a reasonable result is not an obstacle. It is not without reason that a highly specialized service industry has established itself, which sets up and performs CFD simulations for customers and interprets them in a result-oriented manner. With ADVISIM3D, with its approach to maximally reduce complexity, this is not necessary. Here, only spray shadow, volume flow and the cleaning effect that can be achieved with a standard contamination are of interest - no individual and intermediate effects, no turbulences or turbulence.

Our and many of our customers' practical recommendation is therefore: both and, instead of either or. With ADVISIM3D, you can make the perfect nozzle configuration the starting point of the comprehensive CFD simulation for any subsequent detailed investigation, thanks to fast, simple and time- and cost-saving analysis of volume flow distribution and cleaning effect. Unless the cleanability of your tank certified thanks to ADVISIM3D simulation is already sufficient for you.

ADVISIM3D means: Digitize effort - maximize analog benefit.

twitter.com/ADVITEC

twitter.com/advisim3

ADVITEC bei Linkedin

ADVITEC bei XING

Mit ADVISIM3D analoge Prozesse virtualisieren

... analog processes with ADVISIM3D

30 June 2022 | Do you think a manufacturer needs to fully understand his product and its potential before he launches it on the market? Our plant engineers for the biotech, pharmaceutical and food industries just proved us wrong at AnugaFoodTec and IFFA.

They recognize the benefits of ADVISIM3D, the revolutionary virtual simulation software for industrial spray cleaning, primarily in process optimization and automation. Because their pain point lies in the inefficiency and cost intensity of the manual processes surrounding the layout and design of their cleaning systems.

Of course, we were aware that our customers would have to perform time-consuming and resource-intensive analog testing of their nozzles permanently installed in the cleaning environment before ADVISIM3D. This is exactly why we have developed ADVISIM3D over many years to test the type, number and position of linear and rotating nozzles of all renowned manufacturers in a purely virtual environment created according to scientifically determined real data, which can also be quickly and conveniently adapted to any specific requirement. For system manufacturers, this shortens the test series up to the optimal construction and design of a cleaning system and - as we have just learned - also supports their customers in process virtualization, optimization and automation.

We invite everyone who wants to experience for themselves what the technical performance features of ADVISIM3D, such as the spray shadow instant analysis and the visualization of the precise volume flow distribution and the cleaning effect over time, mean for their resource efficiency and workflows: Test the software now without obligation and free of charge in the full version for 30 days in your specific application scenario including product introduction by our specialists.

Contact us at +49 351 65262-22 or use our contact form to receive your personal test license.

We are looking forward to your application scenario.

ADVISIM3D means: Digitize effort - maximize analog benefit.

twitter.com/ADVITEC

twitter.com/advisim3

ADVITEC bei Linkedin

ADVITEC bei XING

From research to practice

Test cleaning effect virtually in real time

8 March 2022 | ADVITEC launched ADVISIM3D in 2021, a groundbreaking software innovation especially for the processing, pharmaceutical and manufacturing industries. As the world's first and only 3D cleaning simulation for industrial container and component cleaning, ADVISIM3D makes cleaning effects virtually testable in real time.

In addition to the direct jet impact, it also takes into account the outflowing fluid as a cleaning component.

Digitalization and virtualization for hygienic design

Specifically, the ADVISIM3D cleaning simulation simulates spray shadows, volume flow distribution and the expected cleaning effect over time. It thus enables the virtualization of time-, personnel- and material-intensive test series in order to save environmental and many other resources in the analog world. On the one hand, the application can thus make a significant contribution to digitally supported hygienic design for machine and plant manufacturers. On the other hand, the design-optimizing use of ADVISIM3D also helps to prevent the widespread oversizing of cleaning systems for the purpose of generous safety buffers. And even existing systems can be virtually checked for optimization potentials thanks to ADVISIM3D and optimized with a manageable investment risk.

ADVISIM3D as a digital tool for the design and assessment of spray cleaning systems thus benefits engineers involved in tank cleaning with static and rotating systems, the cleaning of complex processing plants, and industrial component cleaning.

Closeness to reality thanks to physically determined real data

The basis of the ADVISIM3D cleaning simulation is real data, which has been determined by the Fraunhofer IVV Dresden over many years by means of a very complex physical measurement and evaluation procedure. In this process, the technical measuring stand is individually adapted to each individual nozzle. These real measurement data are integrated into ADVISIM3D in order to guarantee the realism of the virtual simulation results.

ADVISIM3D as the result of an ADVITEC research partnership

ADVISIM3D is the result of the BMBF-funded research partnership SIMKOR and is continuously developed in terms of UX and functionality. Interested parties can apply for free test licenses without functional restrictions and test the 3D cleaning simulation in their specific plant scenario. More at www.advisim3d.de.

You can meet the ADVISIM3D specialists for virtual cleaning simulation in person at the leading trade fair IFFA 2022, "Technology for Meat and Alternative Proteins" in Frankfurt a. M. from May 14 to 19, 2022.

ADVISIM3D means: Digitize effort - maximize analog benefit.

twitter.com/ADVITEC

twitter.com/advisim3

ADVITEC bei Linkedin

ADVITEC bei XING